1. Single-sided FPC flexible circuit board

Lowest cost. When the electrical performance requirements are not high, and can be single-side wiring, the single-side flexible circuit board FPC should be used. This most common form has found commercial applications, such as ink cartridges for printers and memory for computers. The single flexible plate has a layer of chemically etched conductive pattern, and the conductive pattern layer on the flexible insulating substrate is calendered copper foil. Insulating substrates used for flexible assembly can be polyimide (Kapton), polyethylene terephthalate (PET), aromatic amide fiber paper (Nomex) and polyvinyl chloride (PVC).

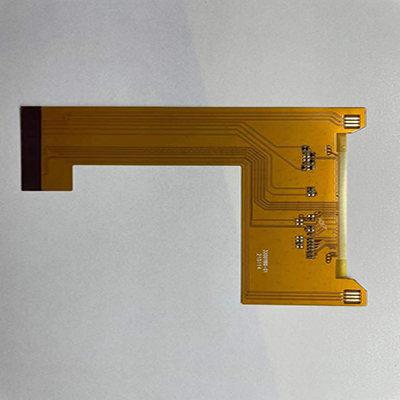

2. Double-sided FPC flexible circuit board

Double-sided FPC flexible circuit board is a conductive pattern etched on each side of the substrate film. Metallized holes connect the shapes on both sides of the insulating material to form conductive paths to meet the design and use of flexure. And the covering film can protect the single and double - sided wire and indicate the position of the element.

3. Multi-layer FPC flexible circuit board

Multi-layer FPC flexible circuit board is three or more layers of single-side FPC flexible circuit board or double-side FPC flexible circuit board laminated together, through drilling, electroplating to form a metallized hole, in different layers to form a conductive path. In this way, there is no need to use complex welding process. Although the number of conductive layers designed to be of this flexible type can be unlimited, the interaction of assembly size, layers and flexibility should be taken into account when designing the layout to ensure convenient assembly.

4. Rigid-flex combination

Traditional rigid flexible plates are composed of rigid and flexible substrates pressed together by selective layers. Compact structure with conductive connections formed by metallized holes. For reliability and price considerations, manufacturers should try to keep as few layers as possible.

Four common FPC flexible circuit boards

HDI rigid-flexible board: High Density Interconnection (HDI) rigid-flexible printed circuit board is a high-end printed circuit board product. Its goal is to meet the growing needs of electronic products toward miniaturization, High frequency, High speed and multi-function. HDI rigid flexible combined board has the advantages of popular HDI board and rigid flexible combined board, which promotes the high integration and high intelligence growth of electronic system design and production. It has been widely used in high-end electronic products such as aerospace skills, medical equipment and cost.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA