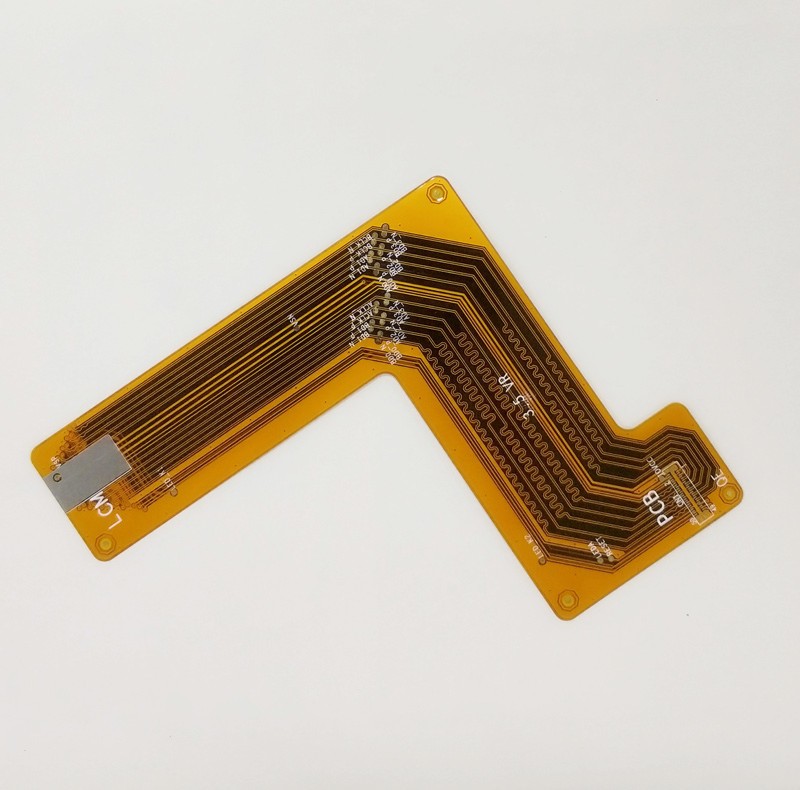

The welding procedure of flexible circuit board is as follows:

1. Before welding, apply flux on the pad and treat it again with the soldering iron to avoid bad tin plating or oxidation on the pad, resulting in bad welding. Chips generally do not need to be treated.

2. Use tweezers to carefully place the PQFP chip on the flexible circuit board, taking care not to damage the pins. Align it with the pad, ensuring that the chip is placed in the correct direction. The flexible circuit board set the temperature of the soldering iron to more than 300 degrees Celsius, dip the tip of the soldering iron head with a small amount of solder, press down the aligned position of the chip with a tool, add a small amount of flux to the two diagonal positions of the pin, still press down the chip, weld the two diagonal positions of the pin, so that the chip is fixed and can not move. Recheck chip alignment after soldering diagonal. If necessary, it can be adjusted or removed and re-aligned on the PCB.

3. To begin welding all pins, add solder to the tip of the soldering iron and apply flux to all pins to keep them wet. Touch the end of each chip pin with the tip of the soldering iron until you see the solder flowing into the pin. When the flexible circuit board is welding, it is necessary to keep the tip of the soldering iron in parallel with the soldering pin to prevent the overlap due to excessive soldering tin.

4. After soldering all the pins, wet them with flux to clean the solder. Suck off excess solder where needed to eliminate any short circuits and lap joints. Finally, use tweezers to check for soldering. After the check is complete, remove flux from the flexible circuit board, dip a stiff brush in alcohol and wipe it carefully along the pin direction until flux disappears.

5. Patch resistance and capacitance components are relatively easy to weld, you can first point tin on a solder spot, and then put on the end of the component, with tweezers to clamp the component, after welding a head, and then see if it is put right; If it is, weld the other end.

Polly peak as a professional FPC flexible circuit board factory, we in the direction of the digital camera, car satellite positioning device, liquid crystal TV, notebook computer, medical instrument, intelligent robot, mobile phone and so on are involved in the communication field and research and development, thank you very much for support for polly peak, many customers are willing to work with us hand in hand advance together, welcome more customers come to discuss cooperation.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA